Shell Mould Casting is a process by which molten metal is gushed into matrix of thin walled shell pair. This pair is made up by applying Sand-Resin around a heated Metallic Pattern.

Large amount of casting is done by using this technique as it ensures better profitability. Carbon steel, alloy steel, stainless steel, low alloys, aluminum alloys, copper, are all cast using shell molding process. The Casting that require fine precision and accurate dimensions are casted using this technique.

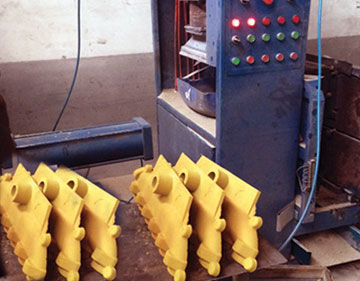

Our Company also produces castings using Shell Moulding. This technique is widely used as the whole process can be automated which enables easy casting and speedy manufacturing of castings. (Company Name) specializes in this moulding as we know the importance of time when it comes to creation of castings at significant time. So do test upon us for Shell Moulding technique of Cast Production.